Showroom

Chemical reactors enable controlled chemical processes, synthesis, and reactions at industrial and laboratory scales. Designed for safety, efficiency, and precision, chemical reactors support consistent production and innovation in pharmaceuticals, chemicals, and material industries. They are vital for scalable and reproducible chemical manufacturing.

Heat exchangers facilitate efficient thermal energy transfer between fluids in industrial, HVAC, and chemical processes. Designed for reliability and durability, heat exchangers optimize energy consumption, maintain temperature control, and enhance process efficiency across multiple applications in manufacturing and utilities.

Pressure vessels safely contain gases or liquids under high pressure for industrial, chemical, and energy applications. Engineered with strength and precision, pressure vessels ensure compliance with safety standards, optimize storage efficiency, and support critical operations in manufacturing and energy sectors.

Storage silos provide safe, organized, and efficient storage of bulk materials such as grains, powders, and chemicals. Designed for durability, ease of access, and capacity optimization, storage silos ensure operational efficiency and protection of materials in industrial, agricultural, and manufacturing environments.

Storage tanks offer secure containment for liquids and gases across industries, ensuring safety, hygiene, and operational efficiency. Built with durable materials and advanced designs, storage tanks support process continuity, inventory management, and long-term reliability in chemical, water, and fuel storage applications.

Reaction vessels facilitate chemical transformations under controlled conditions for industrial and laboratory processes. Engineered for safety, efficiency, and precision, reaction vessels support high-quality production, scalable reactions, and reliable experimentation in chemical, pharmaceutical, and material industries.

Octagonal blenders ensure uniform mixing of powders, granules, and other materials in pharmaceutical, chemical, and food industries. Designed for efficiency and consistency, octagonal blenders optimize blending processes, maintain product quality, and enhance production reliability in industrial settings.

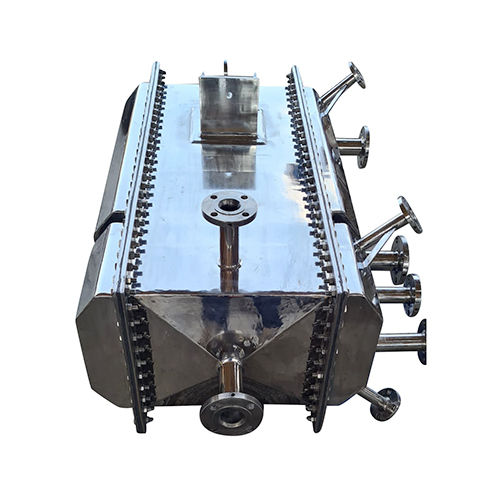

Box type heat exchangers deliver efficient heat transfer in compact, enclosed designs suitable for industrial and chemical processes. They offer reliability, thermal efficiency, and durability, supporting controlled temperature management, energy optimization, and operational continuity in multiple applications.

Distillation columns separate components based on volatility for chemical, pharmaceutical, and petrochemical processes. Engineered for precision and efficiency, distillation columns optimize product purity, throughput, and operational control, enabling high-quality separation and industrial scalability.

Sparkler filters provide effective filtration of liquids and slurries in chemical and industrial processes. Designed for durability and precise separation, sparkler filters ensure high-quality output, maintain process efficiency, and prevent contamination in various manufacturing operations.

Agitated Nutsche filter dryers combine filtration and drying in a single unit for chemical and pharmaceutical applications. They provide efficient solids-liquid separation, uniform drying, and contamination-free operation, enhancing process control and production reliability in industrial environments.

Send Inquiry

Send Inquiry Send SMS

Send SMS